Recent information from Tesla Motors CEO Elon Musk and other sources suggest that the Model 3 production cost could come in as low as $28,000 once production is ramped up to about 10,000 cars a week. One German company also made an interesting revelation about the Model 3 battery, which could give Tesla quite a big advantage over its key competitors in the EV space.

The current goal of the Model 3 is to reach 5,000 cars a week, which will allow the company to roll out more than 250,000 units over the course of 52 weeks. Doubling that will mean meeting the entire reservation requirement within a year.

One source that provided this information is a German company specializing in teardowns. One of its engineers stated that the Model 3 “will deliver a significant positive contribution to earnings” once production hit the 10,000 cars a week level.

This matches Musk’s confirmation in a recent tweet from Fred Lambert of Electrek asking him if the cost will go down to that level at that particular production mark.

That being said, Tesla might not have immediate plans to ramp up to that rate of production. There are still several bottlenecks being addressed at the production line, so we might be a few months or more away from seeing that kind of production rate for the Model 3.

The Real Revelation

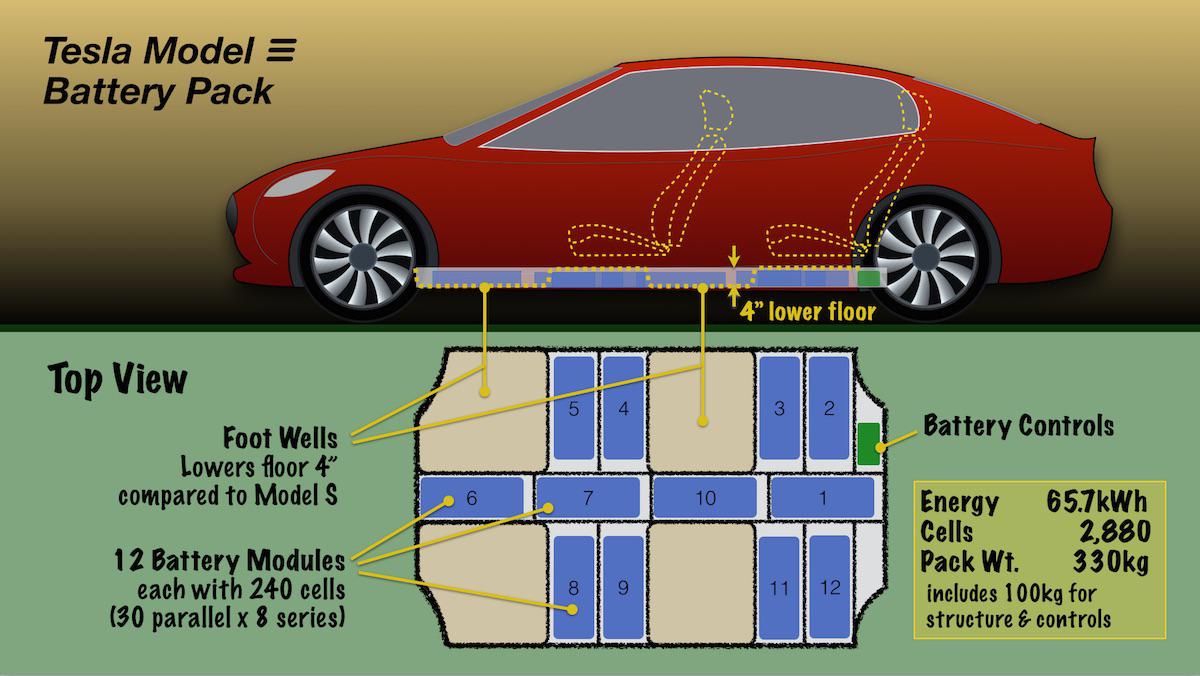

One of the things revealed in the teardown is that Tesla’s batteries use up to 65 percent less Cobalt (2.8% against the standard 8%), which is hard-to-get material on the global market.

That could give the Model 3 an additional cost advantage. It also means having a technology advantage over other EV makers, who will be forced to spend more on their batteries just to try and match Tesla’s range. Even GM has only been able to hit 238 miles with the Bolt, so it remains to be seen how other EV makers can bridge that gap. It could mean a significant time advantage to Tesla as well, while others try and play catch with their own battery tech.