When Tesla CEO Elon Musk wrote “The Secret Tesla Motors Master Plan“, he summarized his plan like this.

- Build sports car

- Use that money to build an affordable car

- Use that money to build an even more affordable car

- While doing above, also provide zero emission electric power generation options

As you can see, the plan was to keep the price of Tesla products on a steady downward slope. That’s exactly what the company has done in the last decade. They started with the very expensive Tesla Roadster (2008), then they launched the less expensive Model S and Model X, and then they launched Model 3, which is still reasonably expensive and hoping to achieve a $35,000 price point very soon – and possibly move even lower after that.

But is that possible? If you are reading this article then you must have gone through plenty of articles that talk about why Tesla will never build a $35,000 Model 3. As if completely ignorant of that noise, Elon Musk is now talking about a possible $25,000 all-electric car a few years down the road. Here is a list of four reasons why Tesla thinks its possible to reduce its average selling price.

1. Economies of Scale

One cannot stress enough about this factor. But for whatever reason, people never talk about it unless they work for Tesla or their name is Elon Musk. Not a single time I have heard Wall Street analysts grilling Elon Musk & Co during their earnings calls to find out how much benefit scale will bring to the table. Though Tesla is pulling as many levers as it can to reduce spending, the path to profitability – sustained profitability – relies on how much per-unit costs will drop as Tesla moves from 100,000 units to 200,000 units to 400,000 units.

If per-unit manufacturing cost is going to stay the same when you double and triple and then double your production again, then no one in the world will ever build factories. We can all say good buy to all our industries.

“When more units of a good or a service can be produced on a larger scale, yet with (on average) fewer input costs, economies of scale are said to be achieved. Alternatively, this means that as a company grows and production units increase, a company will have a better chance to decrease its costs. According to this theory, economic growth may be achieved when economies of scale are realized.”

2. Experience Curve

The benefits of experience are a bit hard to measure for manufacturing companies. A lot easier for humans, but it’s a real thing and it can help in a big way to reduce costs. Tesla itself is a great example for past experience playing a huge role in reducing future costs.

A lot has been written about Tesla shooting itself in the foot with over-automation. What has not been spoken about is how much of toll it extracted from Tesla’s bank accounts, and how much the company will save in the future because of not repeating such mistakes.

We can start by analyzing why Tesla thinks Gigafactory 3 in Shanghai will only cost around $2 billion when the current one, Gigafactory 1 near Reno, Nevada cannot stop eating a full- course-money meal and still ask for more.

“The learning curve also is referred to as the experience curve, the cost curve, the efficiency curve or the productivity curve. This is because the learning curve provides measurement and insight into all the above aspects of a company.

The idea behind this is any employee, regardless of position, takes time to learn how to carry out a specific task or duty. The amount of time needed to produce the associated output is high. Then, as the task is repeated, the employee learns how to complete it quickly and that reduces the amount of time needed for a unit of output.”

3. Wright’s Law, 1936

Wright’s law states that progress increases with experience — specifically, that each percent increase in cumulative production in a given industry results in a fixed percentage improvement in production efficiency.

Wright’s law proves that the experience curve is real, and what’s important to note here is it improves production efficiency. Though there have been several technological advancements in our era, the manufacturing world has only seen incremental improvements over the last several decades.

The difference is stark if you compare it with the tech industry. The Tesla factory in Fremont was run by Toyota and General Motors in its previous avatar. Known as the NUMMI plant, (New United Motor Manufacturing, Inc.), at its peak, this factory shipped out 428,633 units in 2006.

Tesla peak capacity is already over 7,000 units per week and racing towards 8,000 units per week. But what must be noted here is Tesla wants to build 600K units a year, that’s a mind boggling 39% more than what NUMMI did at its peak.

How is this possible? Production efficiency or experience – or is that why Tesla remains one of the most automated auto companies in the world? How much will per-unit cost will drop when Tesla produces 600,000 units in 2019 compared to 100,000 units it built in 2017?

A sixfold increase will make a huge difference. It has to.

4. Mr. Henry Ford

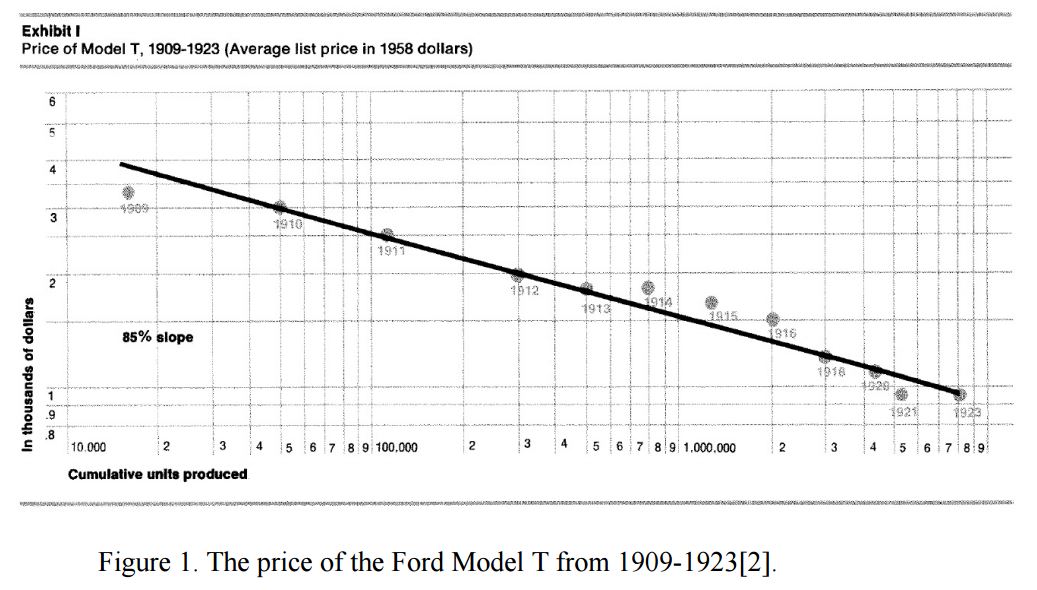

Henry Ford is not a reason, but a proven example that scale and experience can help manufacturing companies hold price on a steep downward slope.

Henry Ford’s Model T was a real game changer, one that completely changed the global auto industry. On October 1, 1908, the first Ford Model T was built at the company’s Piquette Avenue plant in Detroit. Between 1908 and 1927, Ford built nearly 15 million Model Ts.

Henry Ford wanted to build affordable cars. In 1909, Model T Touring was sold for $850, not exactly an affordable price point for the masses. But Ford kept driving the price down as production kept increasing.

From $850 in 1909, Model T price dropped to $400 by 1916 and declined further to reach $380 by 1927. A 55% price drop, as sales increased from 1 to 15 million.

Believe it or not, Tesla is following Ford to the T.

Is that why the Ford Model T is one of the only two gasoline cars Tesla CEO Elon Musk owns?

I own two gasoline cars. One is a Model T that a friend gave me and the other is a Series 1 ’67 E-type Roadster. My first love.

— Elon Musk (@elonmusk) October 12, 2017

A Tesla Factory Tour with Elon Musk: