Tesla started production of Model 3 in the middle of 2017. The first production vehicle, a black Model 3, rolled out of Tesla factory in Fremont on July 7, 2017. Tesla CEO Elon Musk become the first owner of a Model 3.

On July 28th, Tesla delivered Model 3 to 30 customers. At the delivery event, Tesla CEO Elon Musk told reporters, “This is a great day for Tesla. It was never our goal just to make expensive cars. We wanted to make cars everyone could buy.”

Tesla had ambitious plans to ramp up Model 3 production. According to original plans the company wanted to build 100 Model 3s in August 2017, increase production to 1,500 cars in September and reach production capacity of 20,000 units per month by December 2017.

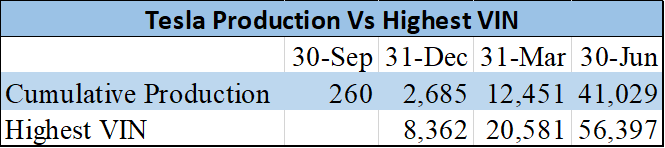

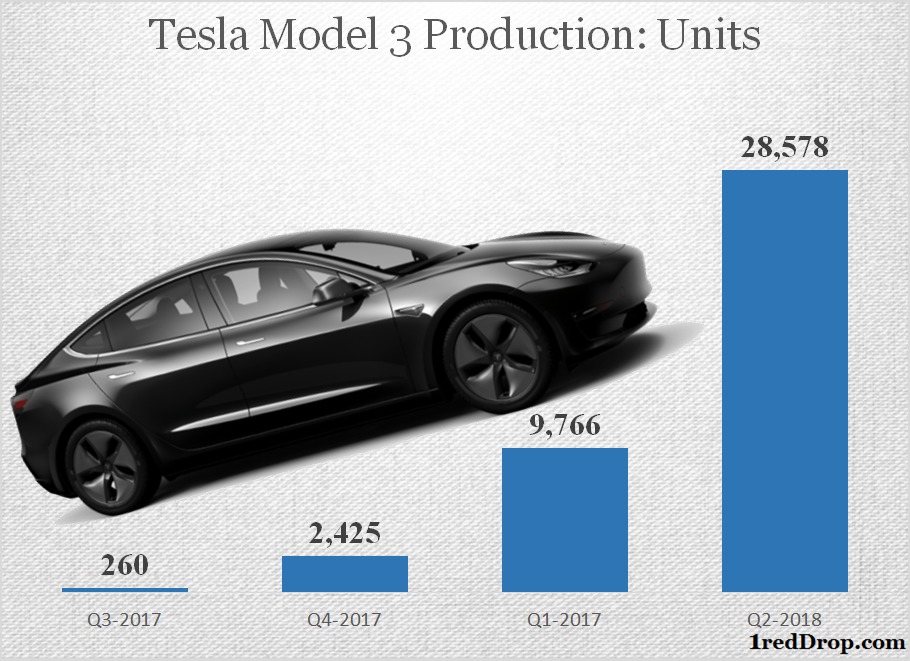

Tesla failed to reach its exponential growth plans, building just 260 Model 3s during the third quarter of 2017, between July-18 and September-18, they built way less than the 1,600 units the company wanted to build.

Tesla’s production struggles continued during the fourth quarter of 2017; between October and December, they built 2,425 Model 3s for the quarter (Q4). Tesla reported that in the last seven working days of December, the company built 793 Model 3s.

Tesla blamed manufacturing bottlenecks for the slowdown. In its fourth quarter 2017 letter to shareholders, the company cited battery production issues at the Gigafactory as one of the reasons for the delay in production.

“What we can say with confidence is that we are taking many actions to systematically address bottlenecks and add capacity in places like the battery module line where we have experienced constraints, and these actions should result in our production rate significantly increasing during the rest of Q1 and through Q2.” – Tesla Shareholder letter

Tesla subsequently lowered its production estimates, and the company announced that it will “target weekly Model 3 production rates of 2,500 by the end of Q1 and 5,000 by the end of Q2”.

In the last seven days of the first quarter and second quarters of 2018 Tesla produced 2,020 and 5,031 Model 3 vehicles, getting close to its target for the first quarter and achieving its target during the second quarter.

In the Q2 update to investors, Tesla said that it had overcome “bottlenecks across various stages of the Model 3 manufacturing process.” The key takeaway from Q2 was that GA3 issues had to be dealt with on priority. The company specifically pointed to the density of lifter robots and their high downtimes as being a constraint to ramping GA3 production to the 5,000 Model 3s a week level.

Tesla took several initiatives to increase its production. The company added a new assembly line – GA4, or General Assembly 4 – under a tent, or Sprung Structure, to help it quickly reach its production target. In the same Q2 shareholder update, the company said this:

To address the short-term issues with GA3, we built GA4 to help us reach our 5,000 units per week target earlier and ultimately to push us past that point. We were able to build GA4 quickly due to the designed simplicity of the Model 3 architecture. The layout and processes of GA4 are similar to those of the Model S and X assembly line, while quality and cost of production are roughly equal to those of GA3. General assembly, excluding the cost of components, accounts for approximately 3% of Model 3 cost. The rest of our manufacturing processes remain highly automated, including stamping, body-welding, paint shop, powertrain assembly and battery pack assembly.

After achieving its 5,000 Model 3s per week target, Tesla wanted to increase production to 6,000 units per week by the end of August and keep increasing production to 10,000 cars/week as quickly as possible.

“We aim to increase production to 10,000 Model 3s per week as fast as we can. We believe that the majority of Tesla’s production lines will be ready to produce at this rate by end of this year (2018), but we will still have to increase capacity in certain places and we will need our suppliers to meet this as well. As a result, we expect to hit this rate sometime next year (2019).” – Tesla Shareholder letter

Tesla produced 53,339 vehicles in the second quarter, delivering 22,319 Model S and Model X vehicles, and 18,449 Model 3 vehicles. A total of 40,768 deliveries were made. In a July 2 news release, Tesla broke down delivery numbers for Q2.

“Q2 deliveries totaled 40,740 vehicles, of which 18,440 were Model 3, 10,930 were Model S, and 11,370 were Model X. Model S and X deliveries are in line with our guidance provided on May 3.”

Tesla expects to produce 50,000 to 55,000 Model 3 vehicles in the third quarter of 2018, an increase of 75% to 92% when compared to previous quarter.

The estimates for Model 3 production in Q3 vary widely, ranging from 51,000+ to 60,000+ for the quarter. Tesla could come in at the high-end of their own guidance of 50,000-55,000 Model 3s produced in Q3, but the one thing that could slow things down is the stringent quality requirements the company has put in place for the Model 3. In the same Q2 update, Tesla said:

“No production target is more important than sustained quality, which is why every vehicle we produce goes through a thorough set of measurements and tests before it reaches the customer. Model 3 quality continues to improve every month and is already on par with Model S and X.”

Significant additional time spent on quality checks could cause another bottleneck in the production line, but efficiencies identified over the past several quarters could compensate and more than make up for that slowdown, in terms of production as well as quality assessments.

Looking forward, Tesla has delayed the 10,000 Model 3s per week target to early 2019 because of supplier constraints holding back capacity increases. We expect the company is pushing its suppliers hard to reduce that time and increase their output so Tesla can meet or beat its ‘early 2019’ timeline. Even if the company is able to hit 10,000 cars a week by February or March, it will give them a big boost in Q1-19 Model 3 production numbers.

At a consistent 10,000 a week level, production numbers for a given three-month period will exceed 120,000 Model 3s and take them closer to fulfilling the still-deep but slowly shallowing pool of reservation holders who haven’t yet received their cars – or even been matched to their VINs.

With 18,440 Model 3 deliveries made during Q2, all eyes will be on Model 3 production and delivery numbers at the Q3 call, not to mention whether or not Tesla will be cash flow positive as guided at the beginning of the fiscal year 2018.

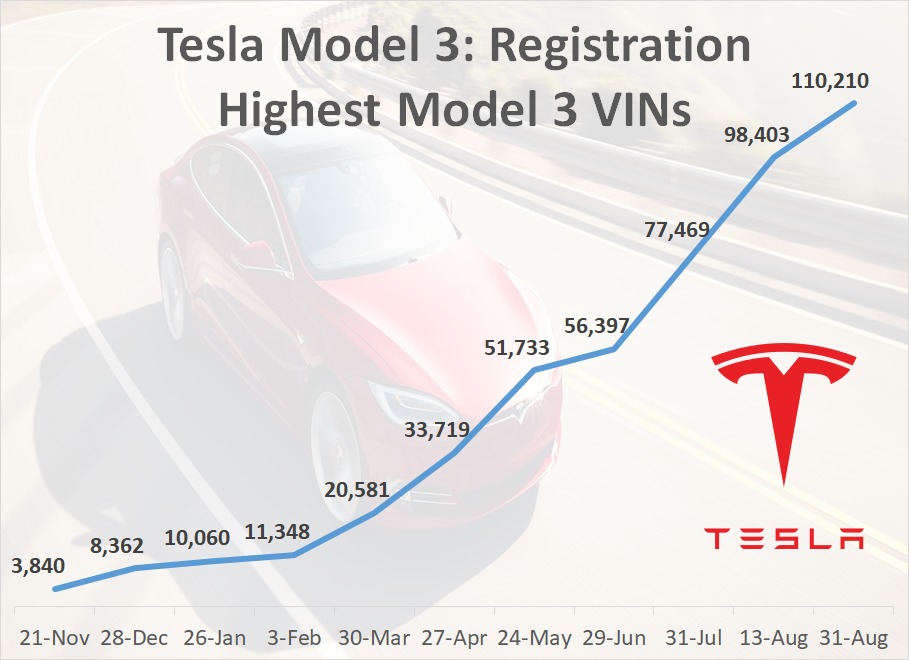

Tesla Model 3 VIN Registrations

Model 3 VIN Registration: Dual Motor All-Wheel-Drive vs Performance edition & RWD

To date, 39,581 dual motor VINs have been registered w/ NHTSA (excl. test batches). This represents ~72% of all VINs registered (54,726) since AWD registrations began on 6/28. pic.twitter.com/Myjvt8T9q9

— Model 3 VINs (@Model3VINs) August 21, 2018